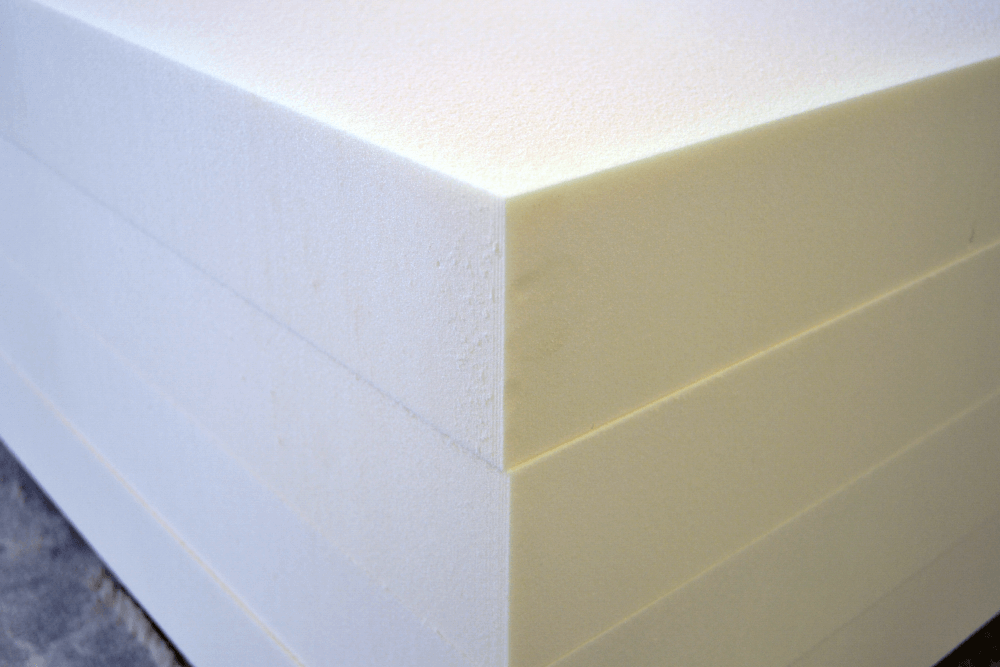

Blocks and sheets with high thermal and mechanical performance, tailor-made products for the insulation industry.

Production of closed-cell rigid polyurethane foam blocks

Criogel is specialized in the production of closed-cell rigid polyurethane foam blocks, obtained through a discontinuous foaming plant. The process, with attention to every detail, makes it possible to obtain high-performance tailor-made slabs, ideal for industrial applications that require thermal insulation, lightness, strength and dimensional stability.

Thanks to an in-depth knowledge of materials, Criogel provides reliable products for the refrigeration industry, mobile refrigeration, shipbuilding and modeling.

The production cycle of polyurethane blocks

1. Foaming of the block

Start of the process with expansion of the material.

2. Maturation

Controlled rest to ensure dimensional stability.

3. Cutting into slabs

The finished blocks are cut into slabs according to the measurements required by the customer.

4. Calibration

The slabs are calibrated to the thickness desired by the customer.

5. Dusting

Dusting the slab of excess dust on the surface.

6. Packaging

Packaging in packages with spacers for transport.

Dimensions and physical-mechanical properties

The rigid polyurethane foam blocks produced by Criogel have an average density of between 35 and 40 kg per cubic metre, a value that represents an excellent balance between insulating power and mechanical resistance.

Density is a fundamental technical parameter when choosing polyurethane, as it directly affects its physical and functional performance.

Thanks to the in-depth knowledge of materials and the ability to adapt the production process to the specific needs of the customer, we supply high-quality, high-performance and versatile polyurethane block sheets for numerous industrial sectors.

Density of rigid polyurethane foam: the balance between insulation and resistance of Criogel

Each Criogel block is the result of a studied balance between thermal performance and robustness.

The density of 35 – 40 kg per cubic meter offers insulating efficiency combined with strength and dimensional stability.

Less density

At about 32-33 kg per cubic meter, the material expresses the best performance in terms of thermal insulation, but the lowest mechanical resistance.

Criogel

Criogel stands between these two values by offering a product that guarantees the best compromise between insulation and resistance. With a density of 35 - 40 kg per cubic meter.

More density

At higher densities, over 50 kg per cubic metre, polyurethane achieves greater mechanical resistance, but less thermal insulation performance.

Advantages of polyurethane blocks

- Excellent thermal performance:

discontinuous foaming with optimal density (35 – 40 kg per cubic meter) for a perfect balance between insulation and resistance; - High stability:

three-dimensional and durable, perfect even for demanding settings; - complete customization: formats of 1200 x 2500 mm, 1200 x 2000 mm or custom-made cut with precision.

- versatilità industriale:

from refrigeration on wheels, to containers, to the naval industry and prototyping and modeling - Consistent quality:

Controlled production process to ensure uniformity and reliability in every batch.

Fields of application

- Refrigerated transport (road and rail): properties such as high insulating capacity and excellent compressive strength make Criogel polyurethane sheets perfect for setting up refrigerated containers and refrigerated vans, offering constant performance over time;

- naval and nautical industry: dimensional stability and compatibility with resins and fiberglass layers make Criogel blocks an ideal solution for the construction of internal structures in boats, where insulation and adaptability are essential;

- modeling and prototyping: easy to cut, shape and process, Criogel polyurethane blocks are widely used in the creation of models for molds, even complex ones, thanks to their internal uniformity and dimensional accuracy;

- Industrial insulation and cold rooms: also used in fixed applications, Criogel blocks represent an excellent basis for industrial thermal insulation systems and in the construction of custom-made cold rooms, where reliability over time is required.

Contact us

Need a custom solution?

We design and create custom cells, blocks, and slabs according to your needs.

Contact us for more information or a quote.